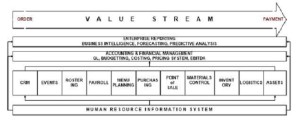

Business is a Value Stream. Contact: John Cleary 0411 522 521

Make customer value the cornerstone of decision-making. Streamline your sequential or concurrent processes, from order to payment, to create value and reduce waste.

Value Stream Mindset and Mapping

Siloed thinking & the ‘cancer of silos’ often undermine customer value.

Value stream thinking challenges staff to see ‘the bigger picture’. To question the:

- value of repetitive non-value-adding tasks that are often taken for granted

- quality of work that fails to meet contemporary standards

- unwritten policies which undermine value

- gut feelings which are contrary to current business intelligence

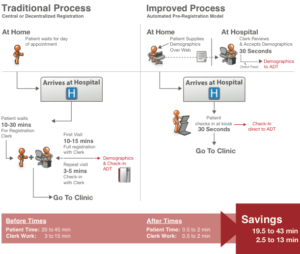

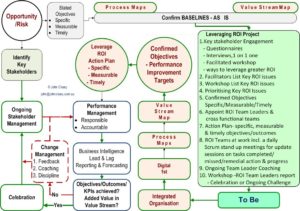

Value stream mapping visually represents flow and identifies opportunities to streamline, create value and eliminate waste (non-value-adding processes).

Value stream thinking and mapping:

- Provide end-to-end visibility & insight into how value is created & undermined

- Break down operational silos by motivating cross-functional collaboration

- Leverage real-time value stream metrics critical to understanding customer value

See Case Studies below which reinforces the view of Peter Drucker in saying:

“There is nothing quite so useless, as doing with great efficiency,

something that should not be done at all.”

Process Excellence

Value Stream Enhancement

Act now. Improving flow along your value stream makes better use of labour, assets, data, inventory, & time for improved cashflow & increased profit.

Value

Value is defined through the “eyes” of the customer based on their experience, research or opinion. Whether Actual or Perceived, value is measured by customer feedback. A positive customer experience enhances long-term customer value.

Value can be Functional, Monetary, Social, & Psychological. Not all are equally important. The importance and ranking of criteria may vary over time.

Value Stream Case Studies

1. Plan Storage

As the client restructured over time, iterative changes in Plan Room operations focused more on tasks and continuity. Multiple previous reviews also took a task and continuity focus with limited consideration of ‘big picture’ issues such as value, productivity, cost, and cost-benefit.

Cost Management Specialists applied a value stream focus and instead of accepting current processes and seeking better outcomes on transport, paper, postage, storage etc., value stream thinking questioned the value of each process. The Plan Room was better able to meet its objectives when 120 processes, which added no value, were eliminated which resulted in annual savings of $1.5m/year.

2. Meat Supply

Competitive tendering of the $600,000+ annual spend on meat for a catering company confirmed that price was just one component of the value.

The new supply agreement resulted in a smaller purchasing list & a significant price reduction. The parties also agreed to a partnership to leverage maximum benefit from the supply chain over the life of their supply agreement including that the:

- client would issue orders a minimum of 24 hours in advance not less than 8 hours.

- supplier would offer higher quality meat at less than market price when seasonal fluctuation created oversupply creating potential to on-sell at a greater margin.

3. Catering Kitchen

Increasing financial challenges led to a Clients request to reduce kitchen costs.

Staff had been reduced yet the complexity of residents’ dietary needs was increasing.

Cost Management Specialists reiterated that, as residents’ dietary needs were a critical success factor, cost was best reviewed in the context of value. Toast three meals/day would reduce cost but would certainly not meet residents’ dietary needs.

Value stream mapping confirmed:

- Skilled & higher-paid staff spent most time of their time doing unskilled tasks

- Base rosters bore little relationship to the need for right staff/place/time/duration

- Cooking commenced hours before serving reducing food quality in Bain Maries

- Portion sizes were not measured and portions varied significantly from plate to plate

- Waste, which staff estimate at 40%, is not measured.

- $16/resident/ day spent on food resulted in $6.40/resident/day being thrown out

- Food waste is value added before becoming an additional cost as garbage

(ordered, stored, prepared, produced, plated, transported, served & collected)

- Incomplete & scattered paper undermined ability to meet individual’s dietary needs

- Purchase orders were faxed with no Par levels & little regard to stock levels

- Goods were received, and paid for, without any reconciliation against orders

- Tasks that could be automated were done manually

- Equipment was not operated contrary to manufacturer’s instruction

- Alternative equipment could free staff time & produce better quality components

Any fool can reduce cost. Value stream thinking identified how to add value considering opportunity cost. Reduction in labour hours was not a solution when meal quality is a critical success factor. An Action Plan outlined priorities to maintain meal quality while removing non-value-adding processes and unnecessary cost.

More Case Studies

Cost Management Specialists have numerous case studies from diverse industries which validate the contribution of value stream thinking to improved financial performance. Equally these Case Studies outline examples of cost reduction or expense reduction that undermined financial performance contrary to their objective.

To discuss Value Stream Enhancement, Process Excellence and Business Process Improvement contact John Cleary on +61 411 522 521 or email roi1@costms.com.au